failure analysis in metallic materials and parts

with the rapid development of science and industry, the quality requirements become more and more important to people. although the quality of materials and the precision of parts have been improved, failure happens occasionally in every walk of life. so it is necessary to get the reason of failure, then we can improve the quality and prevent failure to assure the safe of project.

related industry

auto parts 、precision parts、mould making、casting-forging-welding、heat treatment、surface protection and other metal industry.

common types of failure

defective design (structure design is not reasonable、hardness is not enough、improper material selection、material status requirement is not reasonable);

material defects (loose、blow-hole、segregation、shrinkage cavity、non-metallic inclusion、flakes、surface corrosion and so on)

casting defects (shrinkage cavity and blow-hole、chill and reverted chill、slag inclusion、poornodulizing、segregation carbide、casting crack、graphite floatation and so on)

forging defects (overheating and overburning、forging crack、hot shotness and copper brittleness、forging folds、high-temperature oxidation、annealing is not sufficient、forging flakes、forging flow line)

heat treatment defects(hardening crack、surface decarburization、carburize defects、nitriding defects、temper crack and so on)

cold machining defects (grinding defects 、cutting defects、cold heading defects、stamping/extruding/stretching defects and so on)

the significance of failure analysis

1.to decrease or prevent the same failure, thus to decrease the economics loss and improve the quality of product.

2.provided information for technological development and reform of enterprise; raise the level of product technology and economic benefits.

3.analysis the disable mechanical parts, and make scientific basis for accident confirmation of responsibility 、 detecting of criminal offence、ruling of liability for damage、insurance services、modification of product quality standard.

common tools of failure analysis

(1)fracture analysis

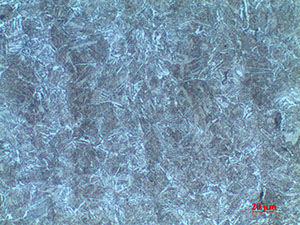

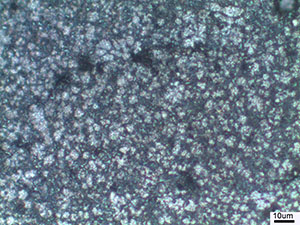

optical morphology analysis;

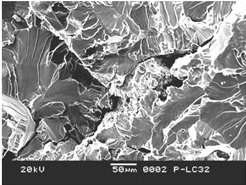

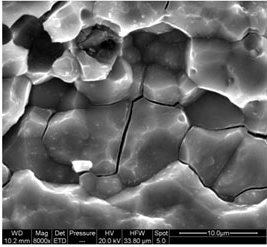

microtopography analysis.

|

|

| cleavage fracture | intergranular fracture |

(2) metallographic structure analysis

(3)component analysis

sem/eds;

icp-oes;

xrf;

oes.

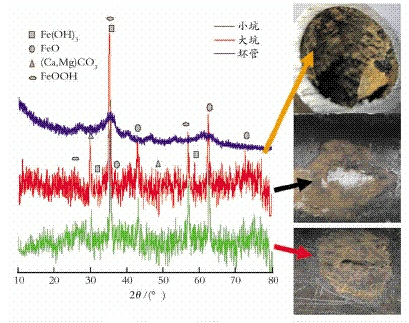

(4)phase analysis

xrd

(5)residual stress analysis

(6)mechanical performance analysis (hardness 、tensile property、bending property)

(7)the process and using environment investigation

- learn more

- qualification and honor

- contact us

- contact us

mtt shenzhen

tel: 400-850-4050

fax: 0755-2782 1672

email: marketing@mttlab.com

mtt suzhou

tel: 400-118-1002

fax: 0512-6275 9537

email: marketing@mttlab.com

mtt shanghai

tel: 400-118-1002

email: marketing@mttlab.com

mtt dongguan

tel: 400-116-1002

email:marketing@mttlab.com