polymer materials

1.abstract

people are constantly put forward various new requirements on the polymer materials as the development of production and science technology. on the whole, the general development trend of technology of polymer materials in the future are high-performance, high functional composite, and intelligent and green. customer demands for high product and process understanding is different because of the high technology of the new requirements and product requirements. fracture, cracking, corrosion, discoloration, and so on phenomena occur frequently on polymer material, which often cause the responsibility of the dispute between supplier and user, so lead to a serious economic loss. then more and more enterprises and units has a new demand for failure analysis of polymer material, which is no longer direct replace material by the previous conventional means, and need to find the root cause and its mechanism of the failure by means of failure analysis method, to improve product quality, process improvement and responsibility to arbitration etc.

2.service object

polymer materials manufacturers: in-depth product failure may cause the design, production, process, storage, transportation and so on stage, explore its failure mechanism, to improve product yield and provide basis for optimizing production processes.

assembly plant: responsibility for arbitration; improve assembly process; to help suppliers terms of the quality of incoming material inspection.

distributors or agents, to provide favorable evidence for the quality responsibility, the responsibility for justice.

the machine user: improve product technology and reliability, improve the core competitiveness.

3.produce benefit

1) it can find out fundamental failure reasons for polymer material, and effectively propose improving suggestions for products design and process;

2) it can provide improving suggestions for products and process; improve products yield and reliability as well as enhance product competitiveness;

3) it can clearly confirm the responsible party of product failure and provide the basis for the judicial arbitration.

4.main failure mode (but not limited to)

fracture, cracking, corrosion, stratification, bubble, coating shedding, discoloration, abrasion failure etc.

|

|

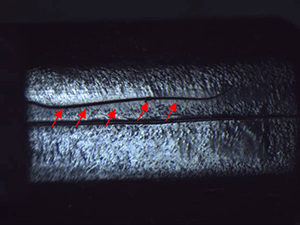

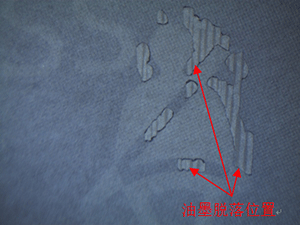

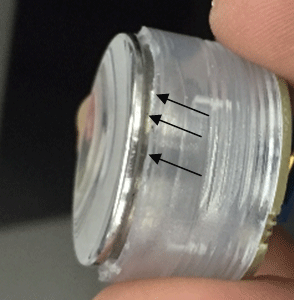

| discolor failure of plastic frame | cracking failure of plastic connector |

|

|

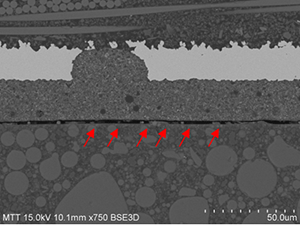

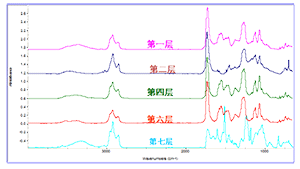

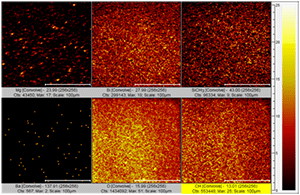

| ic delamination failure | shedding failure of multilayer ink |

|

|

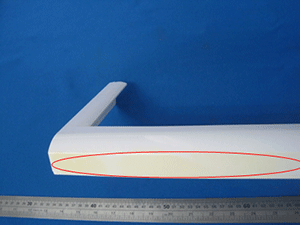

| fracture failure of elevator button pc frame |

5.common failure analysis technology

material component analysis

microscopic fourier transform infrared spectrum analysis(ftir)

microscopic confocal raman spectrometer(raman)

scanning electron microscopy and energy spectrum analysis(sem/eds)

x-ray fluorescence spectrum analysis(xrf)

gas chromatography - mass spectrometry instrument(gc-ms)

pyrolysis gas chromatography - mass spectrometry(pgc-ms)

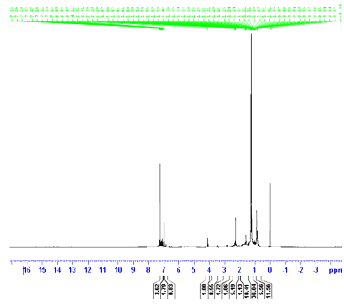

nuclear magnetic resonance analysis(nmr)

auger electron energy spectrum analysis(aes)

x-ray photoelectron spectroscopy analysis(xps)

x-ray diffractometer(xrd)

time-of-flight secondary ion mass spectrometry(tof-sims)

|

|

|

|

|

|

|

material thermal analysis

differential scanning calorimeter method

thermogravimetric analysis

thermal mechanical analysis

the dynamic thermal mechanical analysis

material pyrolysis analysis

gel permeation chromatography analysis

melt index test

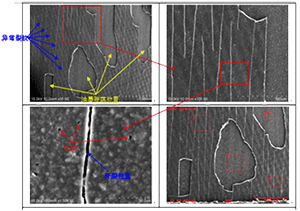

the material fracture analysis

asana microscope

scanning electron microscopy analysis

the physical properties of material test

the tensile strength, bending strength, etc

failure emersion/verification

- learn more

- qualification and honor

- contact us

- contact us

mtt shenzhen

tel: 400-850-4050

fax: 0755-2782 1672

email: marketing@mttlab.com

mtt suzhou

tel: 400-118-1002

fax: 0512-6275 9537

email: marketing@mttlab.com

mtt shanghai

tel: 400-118-1002

email: marketing@mttlab.com

mtt dongguan

tel: 400-116-1002

email:marketing@mttlab.com