- testing

- morphology observation

- microstructure analysis

- surface element analysis

- surface foreign body

- component analysis

- mechanical property test

- thermal analysis

- welding qualification

- ct scan

- nondestructive testing

- cross section analysis

- coating thickness

- flame retardant test

- abration test

- coating quality inspection

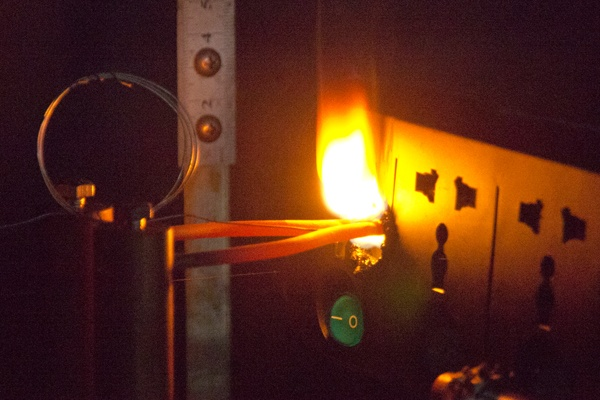

glow wire test

| vertical flammability test | the oxygen index test |

| glow wire test | horizontal flammability test |

| needle-flame test | flammability of interior materials |

definition:

flame retardant test is to use the heating wire with the regulation of the shape and material(¢4 ni80/cr20),heating to test temperature(550 ℃ ~ 960 ℃), after one minutes, vertical burning hot the sample 30 second with this heating wire under one pressure circumstances. then ,according to the sample fire or not ,and how long

it fire ,to measure electrical and electronic equipment’s fire risk.

purpose:

the purpose of the test is to measure the flame ,the glow wire ingnition temperature(gwit) ,the flammability and flammability index (gwfi)of the solid insulating materials.

method:

1.fixed the sample with fixture ,if the sample didn’t have the detailed rules of the thermal stress place ,we always use the top of the hot wire to burning hot the sample,on the thinnest place and the edge of not less than 15 mm.

2.the minimum thickness is 10 mm tightly wrapped in a layer of smooth wood surface white silk paper, positioned below the glow wire applied to test the sample point to 200 ± 5 mm .

3.open the power of the equipment setting the testing time and observation time on 30 second .

4.according to the product standards set up the testing temperature

5.after the test temperature reached, constant for at least 60 s the temperature change no more than 5k ,start the testing switch ,then observe the testing sample and the underlying.recording the duration of the combustion or hot wire at the top of the duration of the applied to the test sample(ti);from the top hot wire applied to the duration of the flame is extinguished(te).

test criteria:

according to the product evaluation standard requirements ,if the product didn’t have requirements respectively satisfy the following 1), 2) the demand for qualified.

1)the test samples didn't burning;

2)satisfy the following conditions at the same time:

a.fire or burning the testing sample, after the hot wire remove, within 30 second the fire put out

b.packing silk paper didn’t burning.

test standard:

gbt 5169.11-2006 electrical and electronic product’s fire danger test par t 11 hot wire basic test method

iec60695-2-11:2000

gb4943-2011

sample size:

the size of the test samples: the length≥60mm; width(the inside of the fixture);thickness:0.75±0.1mm、1.5±0.1mm or 3.0±0.2mm

test schematic diagram

- learn more

- qualification and honor

- contact us

- contact us

mtt shenzhen

tel: 400-850-4050

fax: 0755-2782 1672

email: marketing@mttlab.com

mtt suzhou

tel: 400-118-1002

fax: 0512-6275 9537

email: marketing@mttlab.com

mtt shanghai

tel: 400-118-1002

email: marketing@mttlab.com

mtt dongguan

tel: 400-116-1002

email:marketing@mttlab.com