- testing

- morphology observation

- microstructure analysis

- surface element analysis

- surface foreign body

- component analysis

- mechanical property test

- thermal analysis

- welding qualification

- ct scan

- nondestructive testing

- cross section analysis

- coating thickness

- flame retardant test

- abration test

- coating quality inspection

dynamic secondary ion mass spectrometry (d-sims)

| eds | fib |

| aes | xps |

| d-sims | tof-sims |

1. dynamic secondary ion mass spectrometry

dynamic secondary ion mass spectrometry(d-sims)is a kind of sensitive surface analysis technics. the mass of a trace of secondaryion which is motivated by primary ion from sample surface can be used to determine the type of element, it has a high distinguishability and detective limit. d-sims is able to gain the structure information of element in surface, film, interface, even to three-dimensional samples. d-sims has many characteristics, for example, the secondaryion is from single layer atom (<1nm), with only the information of surface, small analysis area, shallow analysis depth, high detective limit, it is used widely in physics, chemistry, microelectronics, biological, pharmaceutical, space analysis or research and so on.

2. what can d-sims do for clients in product quality?

(1)when the product surface has tiny foreign body, and regular component testing method can't reach accurate qualitative and quantitative analysis to the foreign body, we can choose d-sims. d-sims can analyse foreign body composition of ≥10 um in diameter.

(2)when the product surface film is too thin to use normal test for thickness measurement, we can choose d-dims to analyse, and the use of d-sims help us test ≥1 nm thick film.

(3)when product is multilevel, every film need to be analysed thickness and composition, d-simsis accurate.

(4)when film separate from base material, but foreign body can’t be observed obviously, d-sims can be used to analyse material composition and make sure whether there is pollutant on the section.

(5)in doping process , the content of doping element is normally in ppm to ppb, the depth can reach tens of microns. except d-sims, the regular method can’t detect the concentration distribution of doping element from surface to center.

3. announcement in d-sims

(1)samples size 1×1×0.5cm, too big samples are unacceptable and the surface must be smoothly.

(2)avoid the contact of hands and tools with position which need to be tested, the samples should be put into vacuum package or separate with external environment to avoid polluting.

(3)there is no limitation in electrical conductivity, even insulating samples is acceptable.

(4) element analysis scope h-u, detective limit is ppb.

4. applications example

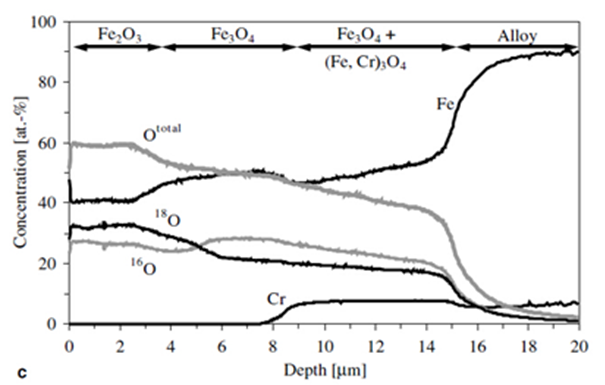

sample information: thickness analysis of anode oxide film in p92 steel.

analysis result:

the thickness of oxide film is 20μm, the distribution from surface to center: 0-4μmfe2o3, 4-9μmfe3o4, 9-15μm(fe.cr)3o4, 15-20μm, alloy.

- learn more

- qualification and honor

- contact us

- contact us

mtt shenzhen

tel: 400-850-4050

fax: 0755-2782 1672

email: marketing@mttlab.com

mtt suzhou

tel: 400-118-1002

fax: 0512-6275 9537

email: marketing@mttlab.com

mtt shanghai

tel: 400-118-1002

email: marketing@mttlab.com

mtt dongguan

tel: 400-116-1002

email:marketing@mttlab.com